Thermal Conductivity: 3.0 W/m·K. This indicates the efficiency of the pad in conducting heat.

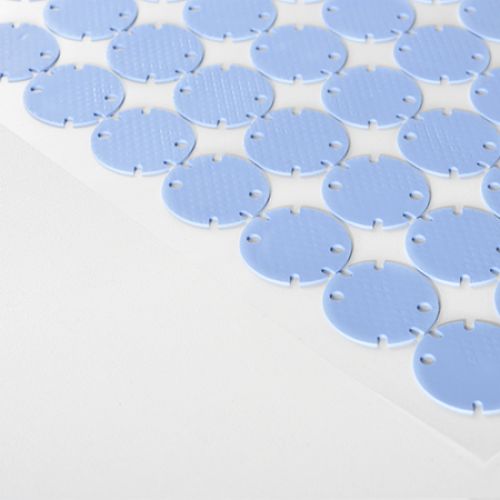

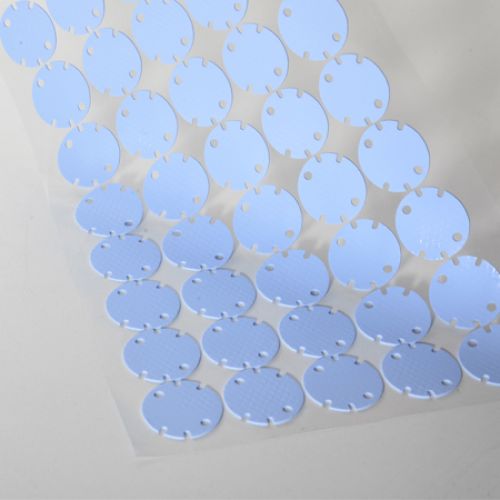

Material: Made of silicone, which offers flexibility, durability, and good thermal performance.

Thickness: Available in various thicknesses to suit different applications and component heights.

Adhesion: Some pads come with adhesive properties for easy application, while others may require mechanical attachment.

Dielectric Strength: Silicone pads often provide electrical insulation, which is important for preventing short circuits.

Compliancy: Silicone pads are soft and can conform to the surface irregularities of components, enhancing contact and thermal transfer.

Improved Thermal Performance: Enhances heat dissipation, reducing the risk of overheating and thermal throttling.

Easy to Apply: Can be easily cut to size and applied without the need for curing or special handling.

Electrical Insulation: Provides electrical isolation, protecting sensitive components.

Durability: Resistant to environmental factors like moisture and temperature variations.

Electronics Cooling: Used in laptops, desktop computers, and other electronic devices to transfer heat from CPUs, GPUs, and other heat-generating components to heat sinks or chassis.

Power Electronics: Applied in power supplies, inverters, and other high-power devices to manage heat dissipation.

LED Lighting: Helps manage heat in LED lighting systems, prolonging the lifespan and maintaining performance.

Automotive Electronics: Used in automotive electronic control units (ECUs) and other critical components to ensure reliable thermal management.

Telecommunications: Applied in telecom equipment to maintain optimal operating temperatures.