Introduction

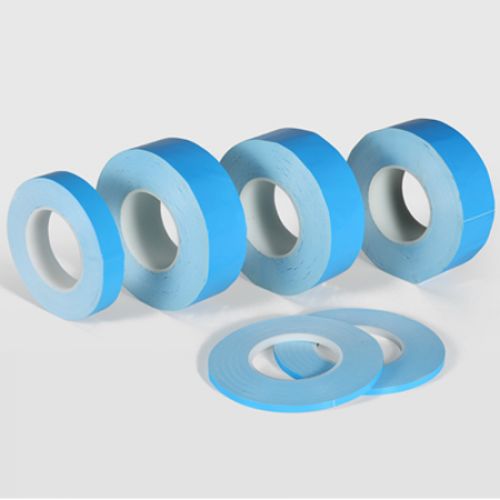

DUOBO 0.25mm Thermal Conductive Adhesive Tape is engineered for long-term operation in temperatures ranging from -20 ~ 120℃. This tape is ideal for application between heat-generating electronic components and heat sinks or metal casings. It effectively addresses the problem of overheating, which can cause reduced efficiency, hardware damage, and system failures. By using our thermal conductive adhesive tape, users benefit from enhanced thermal management, improved device performance, and extended product lifespan.

Features

● Superior Adhesion: Provides strong and durable bonding to various surfaces.

● Thermal Conductivity: Features a thermal conductivity of 1.2W/m.k, ensuring efficient heat transfer.

● Temperature Resilience: Designed to withstand extreme high and low temperatures.

● Flexibility and Conformability: Easily adapts to irregular surfaces for thorough coverage.

● Thin and Effective: With a thickness of 0.25mm, it offers efficient thermal management without compromising space.

● Electrical Insulation: Ensures safe operation by providing reliable electrical insulation.

Application method

● Surface Preparation: Clean and dry the surfaces to be bonded, removing any dust, grease, or other contaminants.

● Tape Application: Cut the tape to the desired length and remove the protective liner.

● Positioning: Carefully place the tape on the intended surface, ensuring proper alignment and a smooth, bubble-free application.

● Pressure Application: Apply firm, even pressure to the tape to ensure a strong bond and optimal surface contact.

● Curing (if required): Allow the adhesive to cure for the recommended duration to achieve maximum bonding strength.

Application

● LED Lighting Systems: Enhances heat dissipation in LED modules, leading to better performance and longer lifespan.

● Consumer Electronics: Ideal for smartphones, tablets, and laptops to ensure effective thermal management.

● Power Electronics: Ensures efficient heat transfer in power supplies and related components.

● Automotive Electronics: Manages heat in vehicle control units and sensors, ensuring reliable performance.

● Industrial Equipment: Provides thermal management solutions for various industrial machines and devices.

Specification

| Testing Item

| Unit

| Testing Value

| Testing Method

|

| Substrate

| -

| Glass Fabric

| -

|

| Colour

| -

| White

| Visual

|

| Thickness

| MM

| 0.25

| -

|

| Peel Strength under 180°

| (PSTC-101)(N/25MM)

| >16

| PSTC-1

|

| Retention

| (1KG/INCH/25°C)

| >48

| PSTC-1

|

| Adhesion

| KG/IN

| 1.4

| PSTC-1

|

| Initial Viscosity

| KG/IN

| 1.3

| PSTC-1

|

| Breakdown Voltage

| KV/MM

| 4

| ASTMD149

|

| Long-term Highest Temperature resistance

| ℃

| 80

| EN344

|

| Short-term Highest Temperature

| ℃

| 120

| EN344

|

| Working Temperature

| ℃

| -20~120

| EN344

|

| Conductivity

| W/M.K

| ≥1.2

| ASTMD5470

|